During the identification installation process, the following issues need to be noted:

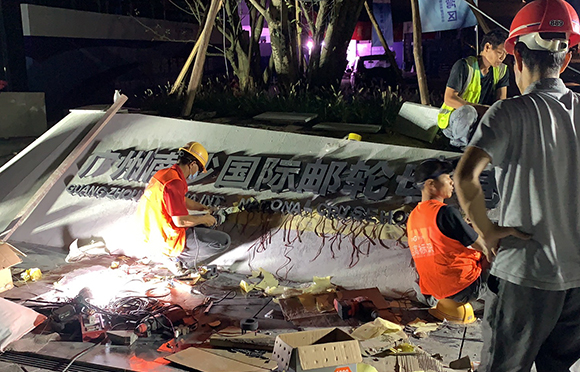

1. Safety measures: Before installing the identification, ensure that appropriate safety measures are taken, such as wearing personal protective equipment such as gloves, safety helmets, and goggles.

2. Material selection: Select identification materials that are suitable for specific environments and applications. Considering factors such as indoor or outdoor, weather resistance, wear resistance, and readability.

3. Surface preparation: Ensure that the installation surface of the identification is dry, clean, and flat. If necessary, perform cleaning and pre-treatment to ensure that the labels can be firmly attached.

4. Installation location: Select a suitable location for identification installation to ensure that it can be easily seen by the target audience. Considering factors such as visual obstructions, light exposure, and observation angles.

5. Installation method: Select the appropriate installation method based on the type and material of the identification. This may include adhesives, screws, nails, or other specific installation tools and techniques.

6. Alignment and Horizontally: When installing signs, ensure that they are aligned horizontally and vertically. Use a spirit level or other measuring tools to ensure accuracy.

7. Remove bubbles: When pasting labels, ensure that the bubbles are completely squeezed out. Scrapers or similar tools can be used to help remove bubbles.

8. Adhesion time: According to the requirements of the marking material, allow sufficient time for the marking to adhere. Follow the manufacturer's recommendations and guidance.

9. Temperature and humidity: When installing the identification, ensure that the ambient temperature and humidity meet the requirements of the identification material. Avoid installing labels under extreme temperature or humidity conditions.

10. Inspection and maintenance: Once the identification is installed, regularly inspect and maintain the identification to ensure it remains in good condition. Repair or replace any damaged or unreadable markings.

These are some issues that need to be noted during the general identification installation process, and the specific situation may vary depending on the identification type and application environment. Before installing the identification, it is recommended to refer to relevant manufacturer guidelines and recommendations to ensure proper installation of the identification and meet specific requirements.